Efficient EPS Block Molding with Advanced Vacuum System and Touch Screen Controls

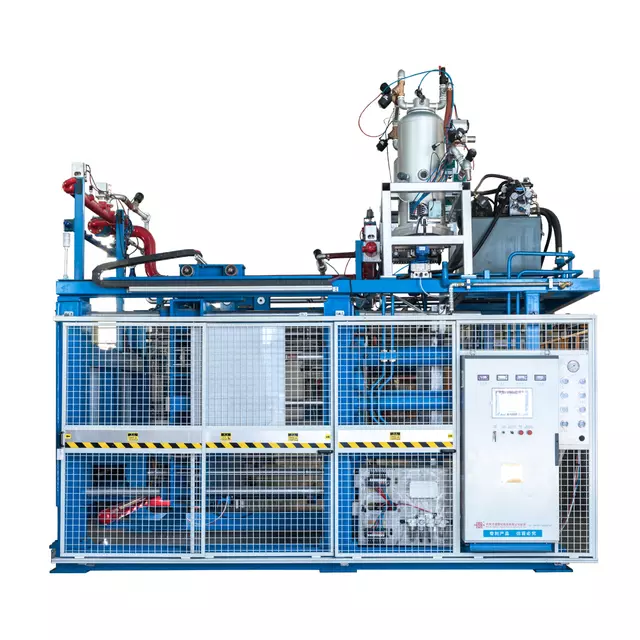

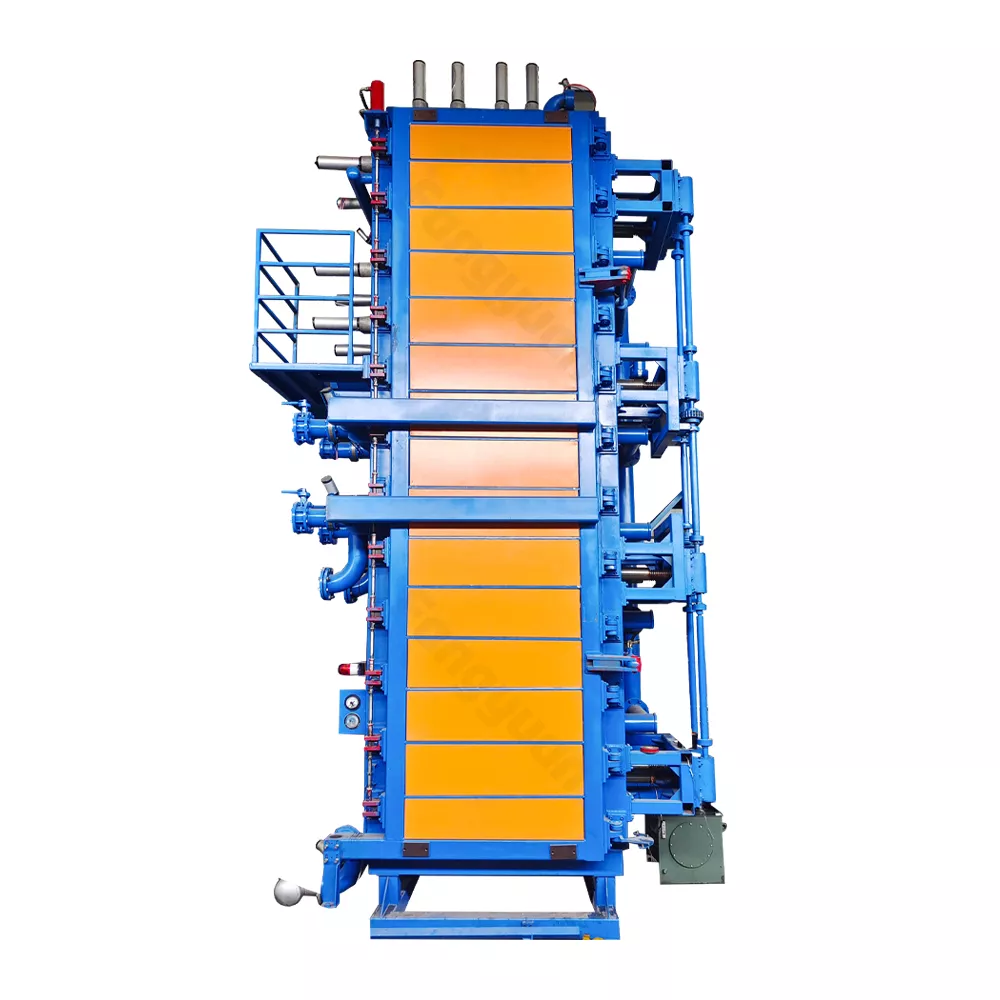

The HS-ZB Series EPS machine excels in efficiency and control with its PLC and touch screen operation, allowing for precise management of critical processes like mould opening, material feeding, steaming, vacuum cooling, and more. This makes it a user-friendly machine capable of high-output production.

One of the standout features is its high-efficiency vacuum system, which helps reduce the moisture content and speeds up the molding process. This makes it ideal for high-density and thick blocks, producing consistent quality across all density ranges.

Constructed from high-strength steel and treated to avoid deformation, this EPS machine ensures durability and the ability to handle the pressure of high-density production. The Teflon-coated mould cavity further improves product quality by making de-molding easy and delivering a polished finish.