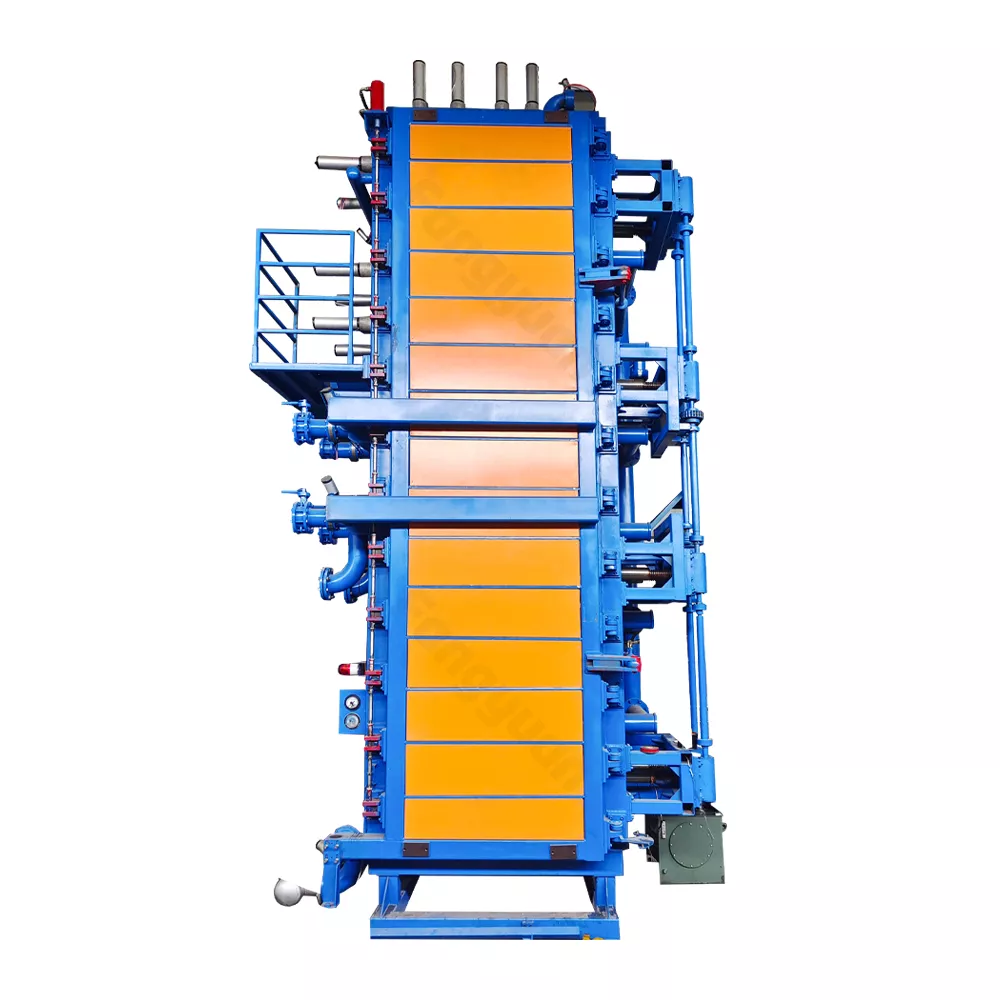

The EPS Machine vertical automatic vacuum block molding system is engineered for maximum efficiency in foam block production. Its vertical mold design is both space-saving and highly effective, enabling manufacturers to produce large volumes of foam blocks in a compact environment.

Equipped with a powerful vacuum system, the EPS Machine ensures quick cooling, reducing energy consumption and shortening production cycles. This results in foam blocks with consistent density, minimal shrinkage, and high dimensional stability, making it a reliable choice for manufacturers seeking high-quality outputs.

The machine’s automation is controlled through a PLC system with a touch screen interface, allowing for precise adjustments and real-time monitoring. With high-quality electrical and pneumatic components, the EPS Machine guarantees smooth operation and long-term reliability, making it an essential tool for any foam block manufacturing process.