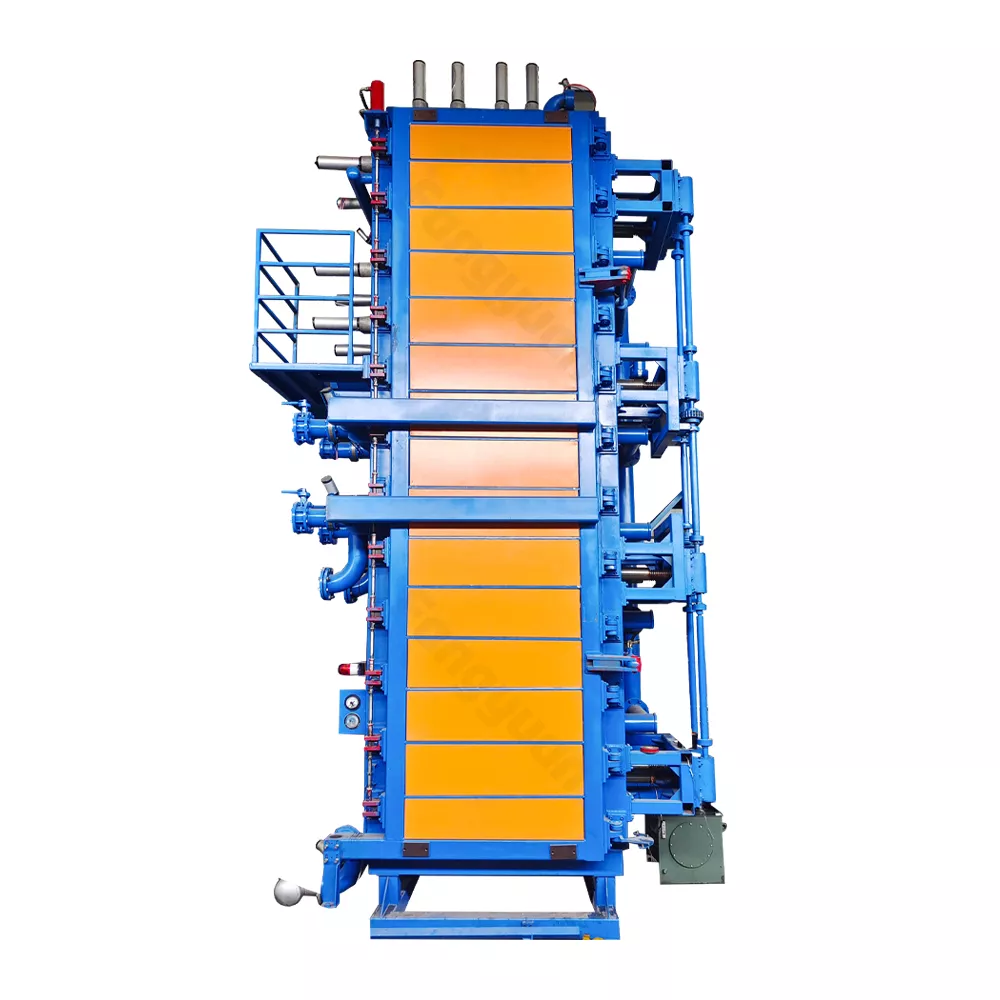

Built with high-strength materials, the EPS Machine is designed for durability and stability. The pipes and steel plates undergo heat treatment, sandblasting, and rust-proof coatings, ensuring the machine's long-term performance in harsh industrial environments. The advanced design boosts efficiency, making it an excellent choice for high-output production lines.

The machine’s unique heating process and vacuum system ensure efficient energy use while delivering strong steam penetration. Foam blocks are cohesive and low in moisture, consistently meeting the high standards required by modern manufacturing.

With a PLC and touch screen control system, the EPS Machine automates the feeding process via material level sensors. It also regulates cooling time using foam pressure sensors, ensuring high precision throughout. High-quality, internationally standardized components make replacement parts easy to source, ensuring low downtime.

The hydraulic system serves as the machine’s central control, ensuring that the door, ejector de-molding, and locking functions operate seamlessly.